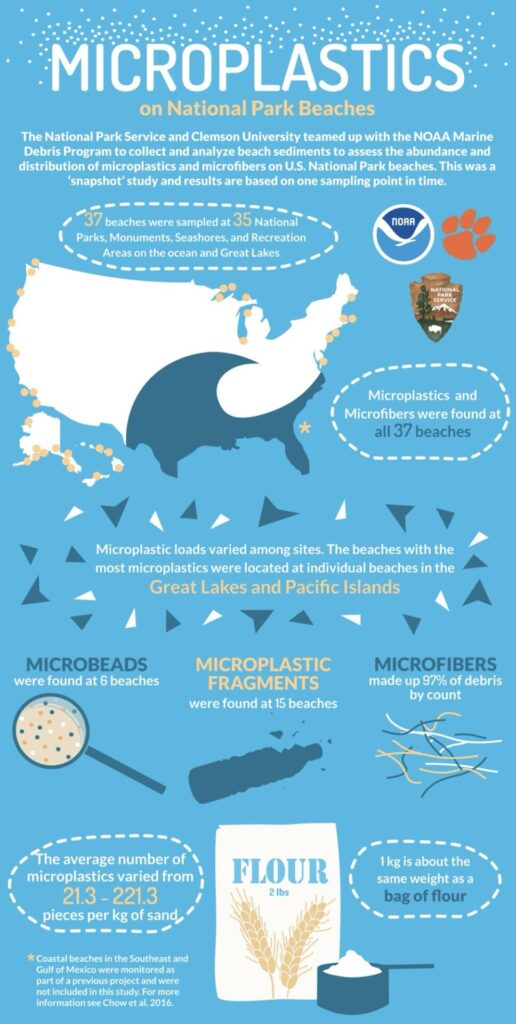

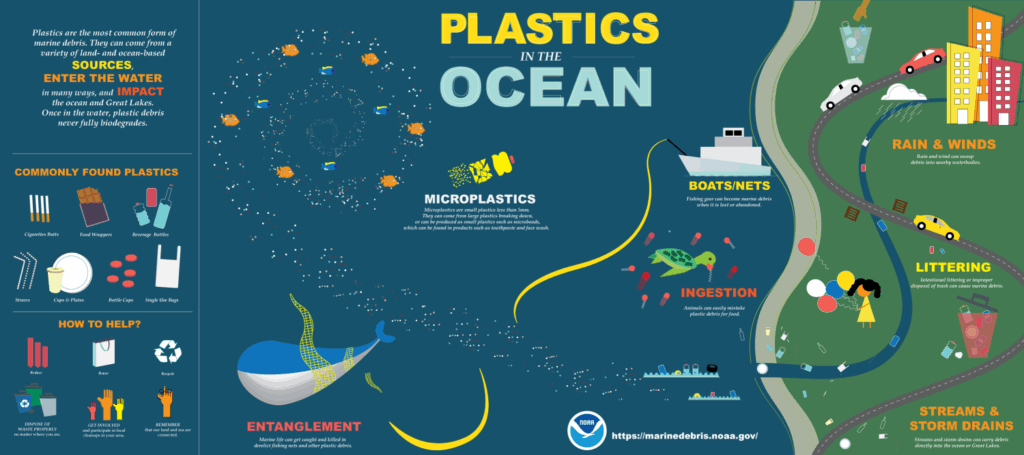

If you spend any amount of time on the water, you’ve probably seen it: faded inflatable dinghies, sticky tubes, chalky seams, bits of material breaking down from years of sun and salt. What many cruisers don’t realize is that these failing materials don’t just disappear — they break down into microplastics that persist in the ocean for decades.

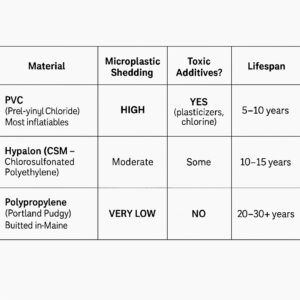

This article explains why PVC and Hypalon inflatables shed microplastics, how this compares to polypropylene (the material used in the Portland Pudgy), and what it means for cruisers who care about their environmental footprint.

PVC: The Most Problematic Microplastic Source

Most inflatables on the market are made from PVC (polyvinyl chloride) — a material that breaks down quickly under UV, heat, and saltwater exposure.

Why PVC sheds harmful microplastics:

PVC contains chlorine (57%), making it chemically unstable in sunlight. It requires plasticizers (often phthalates) to stay flexible. Over time, PVC tubes crack, chalk, and turn brittle, releasing a powder-like residue into the water. The particles can leach toxic additives, including phthalates and stabilizers. PVC-coated fabrics are layered composites, so once they break down, the fragments cannot be recycled.

There is a good reason that PVC is not used for drinking water piping. If you have ever left PVC pipe out in the sun, you know about the material breakdown and white powder on the surface. That’s bad stuff.

In the marine environment, PVC microplastics are considered some of the most harmful due to their chemical load and persistence.

Hypalon (CSM): Better… but Still a Long-Term Waste Problem

Older high-end inflatables used Hypalon (CSM), a chlorosulfonated polyethylene rubber. While Hypalon holds up better than PVC, it still breaks down.

What happens as Hypalon ages:

It forms rubbery flakes and crumb-like debris. The particles contain chlorine and sulfur groups, which do not biodegrade. Over decades, Hypalon slowly oxidizes and fragments, contributing to microplastics that persist indefinitely.

Hypalon no longer being manufactured by DuPont is a reflection of the environmental challenges around its chemistry.

Polypropylene (PP): A Cleaner, Longer-Lasting Alternative

The Portland Pudgy hull is made from UV-stable, thick-wall polypropylene (PP) — a recyclable thermoplastic with one of the cleanest environmental profiles of any marine-use plastic.

Why polypropylene produces far fewer microplastics:

PP contains no chlorine, no plasticizers, and no toxic additives. It is highly UV resistant, meaning it breaks down hundreds of times more slowly than PVC or Hypalon. When PP does shed particles over many years, they are chemically simple, non-toxic, and non-leaching. PP hulls last decades, reducing the frequency of replacement and waste.

Polypropylene is widely recognized as one of the least harmful plastics in marine environments.

Why This Matters to Cruisers

Cruisers see firsthand how sensitive our oceans and anchorages are. What seems like “normal wear and tear” on an inflatable dinghy is, in reality, the steady release of plastic particles into the very water we live on.

A Portland Pudgy isn’t just a safer, longer-lasting tender — it’s also a cleaner choice for the places we love to explore.

More durable.

More recyclable.

Less microplastic pollution.

Built in Maine for people who care about the water.